Glass robots have become indispensable tools in industries such as construction and manufacturing, transforming the way glass is handled and installed. These remarkable machines owe their capabilities to a sophisticated blend of cutting-edge technologies, including sensors, artificial intelligence (AI), and robotics. We will talk in-depth about the technology that makes glass robots work, focusing on the role of AI, robotics, and sensing. Additionally, we will explore how these technologies work together to create efficient and safe glass lift and glazing lift solutions.

Sensors in Glass Robots

Sensors play a pivotal role in the functionality of glass robots. They provide the machines with the ability to perceive their environment, enabling them to navigate, interact, and manipulate glass with precision and safety.

Types Of Sensors

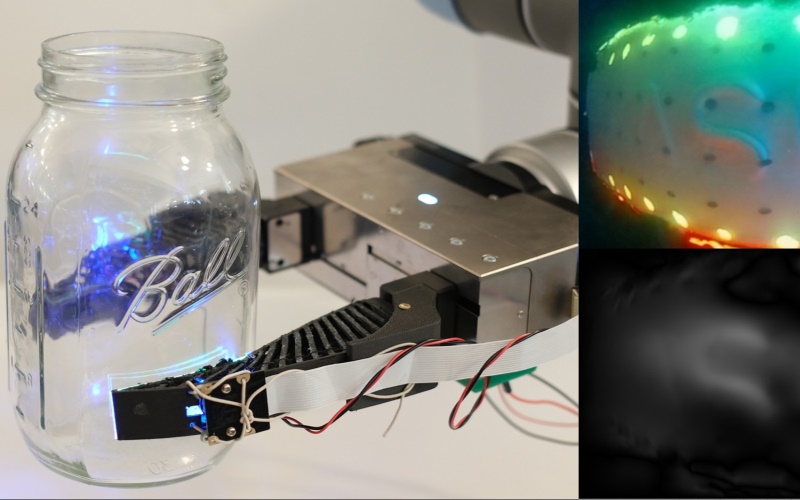

Vision Sensors: Glass robots often incorporate advanced vision systems, which can include cameras and depth sensors. These sensors allow the robot to “see” the glass and its surroundings, ensuring accurate positioning and alignment during lifting and installation.

Force/Torque Sensors: Force and torque sensors are crucial for delicate glass handling. They provide feedback on the force being exerted on the glass, allowing the robot to adjust its grip and pressure to prevent damage.

Proximity Sensors: Proximity sensors help the robot detect obstacles in its path, ensuring collision avoidance during glass lifting and transport.

Load Sensors: Load sensors are vital for monitoring the weight of the glass being lifted. They ensure that the robot operates within safe weight limits, preventing accidents and damage.

Sensory Integration

The coolest thing about glass robots is that they can combine data from many sensors at the same time. Through sophisticated algorithms, these machines can interpret sensory inputs to make split-second decisions. For example, when a glass robot lifts a heavy glass panel, it relies on load sensors to monitor the weight and vision sensors to ensure precise positioning.

AI in Glass Robots

Artificial Intelligence is the brain behind the operation of glass robots. AI algorithms are responsible for decision-making, control, and automation, making these machines intelligent and adaptable.

Object Recognition And Tracking

One of the key applications of AI in glass robots is object recognition and tracking. AI algorithms can identify glass panels’ shapes, sizes, and orientations. This information is invaluable for planning efficient lifts and glazing operations.

Path Planning And Navigation

AI helps glass robots plan their paths and navigate complex environments. It takes into account the locations of glass panels, obstacles, and safety protocols to optimize routes and avoid collisions.

Predictive Maintenance

AI can predict when maintenance is needed based on sensor data. This proactive approach ensures that glass robots are always in peak condition, minimizing downtime and maintenance costs.

Adaptive Control

AI enables glass robots to adapt to changing conditions. For instance, if a sudden gust of wind affects a glass lift, the robot can make real-time adjustments to maintain stability.

Robotics in Glass Robots

Of course, at the heart of glass robots are the physical mechanisms that allow them to execute tasks with precision. Robotics technology is what gives these machines their ability to manipulate glass panels.

Robotic Arms

Glass robots are equipped with robotic arms that mimic human-like movements. These arms are designed to be highly flexible and dexterous, allowing them to handle glass of various shapes and sizes.

End Effectors

The end effectors or grippers at the end of the robotic arms are designed specifically for glass handling. They can be customized to grip glass securely without causing any damage.

Safety Features

Robotic systems incorporate advanced safety features. They have emergency stop mechanisms, collision detection, and fail-safes to ensure the safety of both the operators and the glass being handled.

User Interface

Most glass robots have user-friendly interfaces that allow operators to program and control them easily. These interfaces often include features like joystick controls and touchscreen displays.

Glass Lift and Glazing Lift with Precision

Now that we understand the technology behind glass robots, let’s explore how all these components come together to perform precise glass lifts and glazing operations.

Glass Lift

When a glass robot is tasked with lifting a glass panel, the process begins with vision sensors identifying the panel’s position and orientation. Load sensors ensure that the weight is within the robot’s safe lifting capacity. The AI then calculates the optimal path for the robotic arm to reach the glass panel while avoiding obstacles. The robotic arm, equipped with its specialized end effector, moves into position and securely grips the glass. Force/torque sensors continuously monitor the force being applied to ensure the glass is handled gently.

During the glass lift, the robot’s AI system constantly adjusts for any unexpected movements, such as wind or vibrations. This adaptive control ensures that the glass remains stable throughout the lift. The operator can monitor the entire process through the user interface, with the robot making real-time adjustments to ensure a safe and successful glass lift.

Glazing Lift

Glazing, or the process of installing glass panels, requires even more precision. The glass robot’s AI system plays a crucial role in planning the glazing process. It calculates the exact positions where each glass panel should be installed, ensuring a perfect fit.

The robot’s vision sensors continuously scan the environment to identify the installation locations and guide the robot to the correct positions. Once in place, the robot’s AI-controlled arm gently lowers the glass panel into the designated spot, adjusting for any minor deviations. This level of precision is nearly impossible to achieve consistently with manual labor.

Conclusion

Glass robots are a testament to the incredible advancements in sensor technology, artificial intelligence, and robotics. These machines have revolutionized the glass handling and installation industry by improving efficiency, precision, and safety. Things keep getting smarter, so soon there will be smarter glass robots that will make working with glass even better. For many years to come, glass will still be a useful tool in many areas. Glass lift and glazing lift operations have been transformed by these intelligent machines, ensuring that glass is handled with the utmost care and precision.